E-Archive

Cover Page

in Vol. 3 - August Issue - Year 2002

Shot Peening in Non Transportation Industries

Dave Cooper, Co-Owner of Blastworks Inc.

Blastworks is a Canadian based manufacturer of custom automated Blast Cleaning and Shot Peening equipment for production aerospace, automotive and general manufacturing industries. The company is also the Canadian stocking distributor of Shot Peening support products from Electronics Inc.

The technological marvels that we enjoy in the form of Aircraft and Automobiles have benefited tremendously from the advances and research in Shot Peening. Where these two industries provide much of the glamour in the manufacturing sector of the world economy, and receive most of the interest in the Shot Peening arena, there are other lesser known products that realize great benefits from the peening process.

One such product is Deep Rock Hole Drill Bits used in the Mining, Quarry, Well Drilling and Construction industries. These Drill Bits suffer violent and repetitive impact and torsional stress, often in the quest for the minerals and ore that ultimately allow those more glamourous transportation industries to exist.

An established heat-treating company with multiple locations in Pennsylvania, USA, REX HEAT TREAT was looking to add value to their existing services provided to a manufacturer of Deep Rock Hole Drill Bits. With no prior experience in peening equipment, the company required a system that delivered the versatility to process the wide range of Drill Bits manufactured, literally encompassing hundreds of different designs and sizes.

The solution developed by Blastworks Inc. included some of the features of their more than 30 machines previously built for the Rock Drill Bit industry, while introducing some unique capabilities to solve the application challenges. An indexing multi-table style machine was selected for the benefits realized in unloading and loading the substantial work pieces at an external operator station while the peening process was taking place within the cabinet.

Although the indexing style machine is a common blast and peening solution, one of the challenges encountered was the need to peen opposite ends of the heavy Drill Bits to different peening intensities. To achieve this versatility, the equipment is essentially two machines in one, addressing each particular peening requirement at a dedicated station.

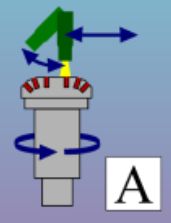

Diagram A illustrates the critical peening area (shown in red) of the Bit head, a series of bores that later accept sharp tipped carbide inserts that are key to the drilling performance. A programmable, dual axis nozzle featuring horizontal travel and nozzle wrist action combines with the rotating workpiece to direct an effective shot stream into the multiple holes which are often arranged at various angles off the bit centre line. A unique hollow satellite table design accepts the Bit shank to simplify loading and unloading as well as fixture design.

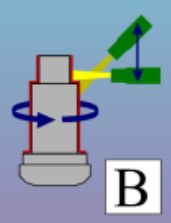

Diagram B illustrates the demand for peening of the external shank portion of the Bit, a process supported by a second set of satellite tables that accept the Bit head for stable orientation. A programmable, vertical travel carriage allows a pair of nozzles to effectively direct their shot stream at the rotating part.

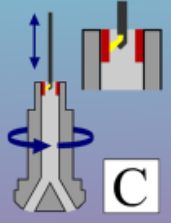

In unison with the external shank peening, the upper shank bore area is peened as illustrated in Diagram C. The vertical travel motion of the previously described carriage is utilized by a deflector style nozzle to effectively peen the shank bore walls, while sharing in the economy achieved by a single carriage.

With a need to integrate dual shot sizes into the production capability, the equipment features a mechanical shot reclaim system that includes both a spiral separator for maintaining shot roundness and a vibratory classifier to ensure shot size consistency and distribution to the appropriate storage hopper. This is "big ball" peening of heavy but compact parts, demanding a rugged machine design with good access for internal maintenance.

All machine process control is accomplished through a touch screen operator interface unit and PLC system controller that allows the creation and retrieval of process recipes to maximize productivity, and retain the flexibility for future product applications.

The processing of Deep Rock Hole Drill Bits is just one of many non-transportation applications that benefit from peening technology. Part designers from all industries are encouraged to consider the benefits of peening in both new product development and as a potential solution to troublesome product performance.

For Information:

Blastworks Inc.

4390 Paletta Court

Burlington, Ontario, Canada L7L 5R2

Tel: +1.905.681 2030, Fax: 681 2814

E-mail: bworks@blastworks.com

www.blastworks.com