E-Archive

Articles

in Vol. 24 - July Issue - Year 2023

A Solution for Multifunctional CNC Shot Peening Machine in the Aviation Industry Introduction

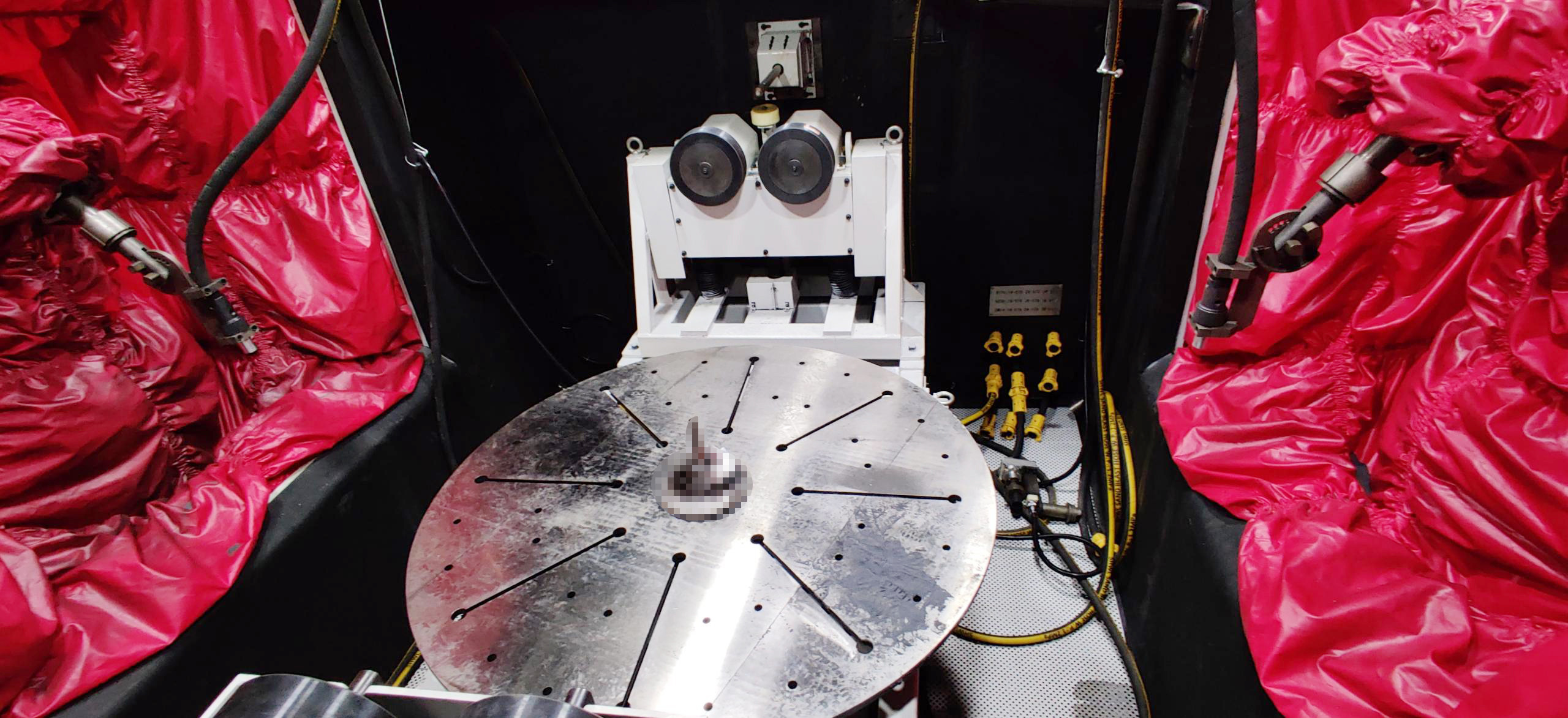

Figure 1: Front view of CNC shot peening machine (machine has a left right symmetrical structure)

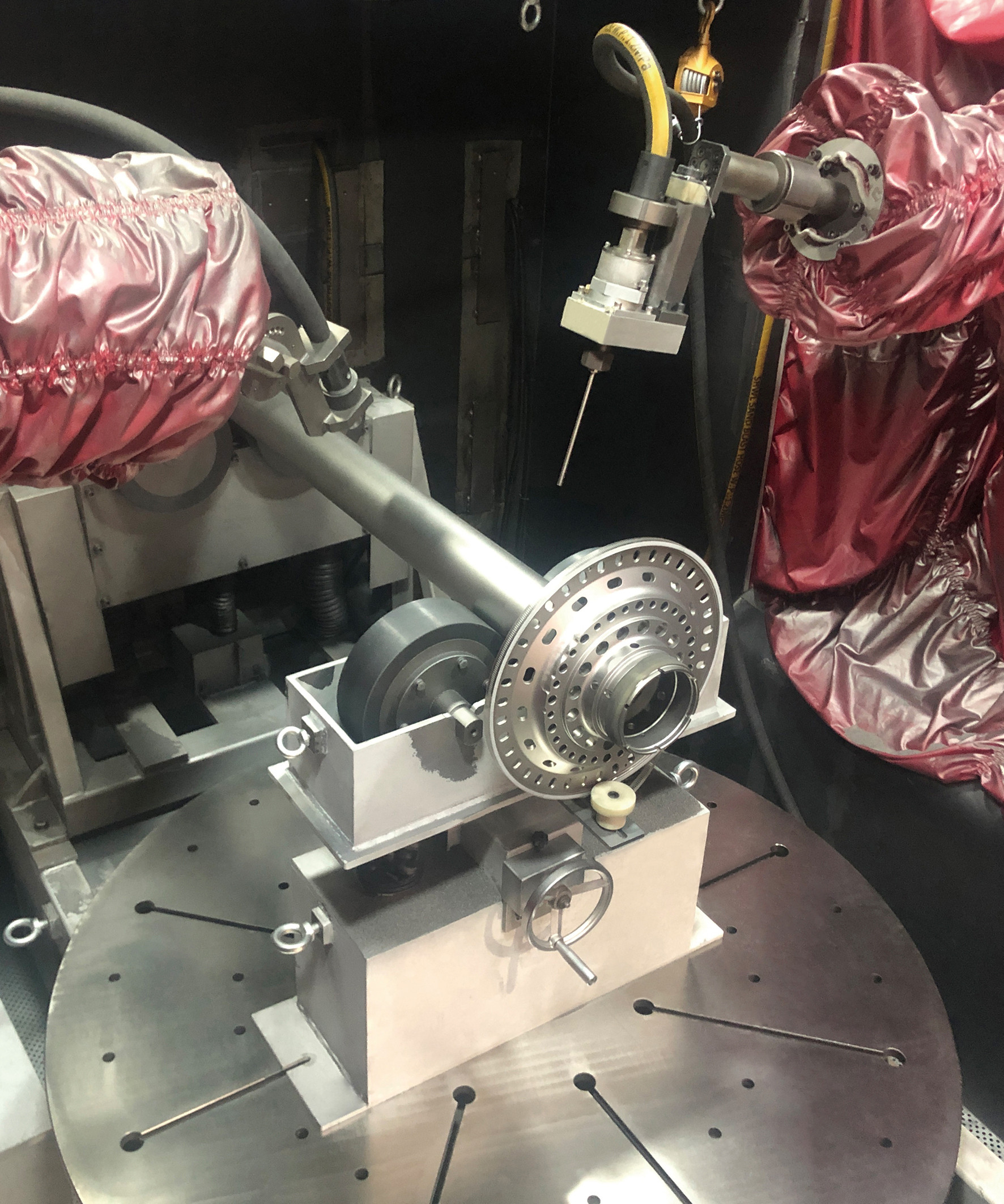

Figure 2: Double robots are shot peening long shaft parts

Figure 3: Interior view of shot peening chamber

In October 2021, Peentech overcame various restrictions caused by the COVID-19 epidemic and delivered a customized CNC shot peening machine to an aviation component manufacturing enterprise as scheduled. Peentech has been focusing on the surface treatment process of metal components for decades, and with its professional knowledge in the field of shot peening, it enjoys a high reputation among metal component manufacturers in China. This CNC shot peening machine is a customized solution tailored by Peentech for the characteristics of aviation components, using shot peening strengthening technology.

The aviation industry has a wide variety of materials, complex designs, and high manufacturing accuracy, resulting in a very precise demand for shot peening machine. The CNC shot peening machine meets these requirements well, equipped with dual robots, three customized nozzles, three abrasive compatible sorting and recycling systems, a fixed turntable, a trolley and track system, a three-axis mechanical module, an abrasive online weighing device, and a comprehensive user-friendly interface, etc., achieving the following functions perfectly:

High component structural compatibility

Aviation components, such as high-precision gear components, long shaft components, complex theoretical structural components such as wing shapes, and numerous thin-walled and deep cavity structural components, all require shot peening strengthening or shot peening forming. This machine can achieve shot peening with the following structures:

Long axis workpieces

The trolley and track system can meet the internal and external profile requirements of long axis workpieces with a maximum length of 2500mm; Horizontal clamping can be achieved for axial workpieces and shot peening can be applied to the external surface. The trolley can be completely moved out of the shot peening chamber for easy workpiece loading and unloading, and can be locked.

Inner hole and groove

The machine is equipped with an outer diameter φ 6.5mm, inner diameter φ 2.5mm inner hole dedicated rotary nozzle, and it can spray small holes with an inner diameter as small as 8mm and grooves with a width as small as 8mm.

Deep hole inner wall

The machine is equipped with a spear nozzle in the horizontal direction, which is driven through a three-axis mechanical module. It has the ability to peen the inner wall of deep holes for horizontally placed parts, with a maximum inner hole depth of 2500mm.

Complex surface workpieces

The machine is equipped with a fixed turntable, which serves as the external servo axis of the robot and can work in collaboration with dual robots. At the same time, it is combined with corresponding nozzle devices to achieve shot peening on different surfaces.

High part material compatibility

With the gradual improvement of aviation machine performance, the materials of aviation structural components are becoming increasingly diverse, and in addition to steel, new high-performance materials are constantly being introduced. The material of structural components is gradually shifting from aluminum alloy to a situation where it is equally important with titanium alloy and composite materials.However, customizing a machine for parts of different materials or cleaning the shot abrasive inside the machine to peen new parts can be costly .

This machine has developed a sorting system that is compatible with both metallic and non-metallic abrasives. In addition to the self-designed sorting system, a magnetic sorting device with a precision on-off valve has been designed and selected to completely separate non-metallic and metallic abrasives. A fully filtered double-layer vibrator is also installed below the sorting device to ensure that the shape and size of the abrasives always comply with AMS 2430 standards. This system solves the problem of machine stagnation caused by traditional machine replacing abrasives, and mixing caused by inadequate replacement of abrasives.

Controllable deformation of parts

The shot peening process can cause certain deformation to parts, but for some aviation thin-walled parts, such as blades, which are typical weak rigid structures, how to control the structural deformation caused by abrasive impact is a test for shot peening machine.

This machine is designed with a dual robot spray system to shot peening large parts. For locally asymmetric areas, a single robot is cleverly used to carry a spray structure with dual nozzles to control the deformation of the parts caused by unilateral force.

At the same time, the stability of the shot abrasive flow rate of each nozzle also affects the deformation amount. According to AMS 2430 standard, it is necessary to pay attention to the abrasive stability of the machine. This machine is equipped with an online weighing device, which can run during sampling or synchronize with the machine. The robot automatically blasts the abrasive into the system, and the system display screen can automatically display the current shot flow rate. At the same time, the abrasive passes through the weighing system and automatically returns to the machine.

Human-computer friendly interface

In the aviation field, the repeatability and traceability of the parts processing process are very important. Peentech has designed a good human-machine interface, which was developed by Peentech's professional electrical team. The human-machine interface can record, store, and monitor all parameters of the machine during operation in real-time, such as nozzle angle, distance between nozzle and parts, dual robot spray trajectory, abrasive flow rate, abrasive stability, etc., and calculate them. If the set limit value is exceeded, the system automatically corrects and sends an alarm to ensure that the parts always perform the same shot peening strengthening process under the same process parameters and accuracy level. At the same time, the data of each part or batch can be copied and saved.

At present, Peentech Group has accumulated rich experience in the design and manufacturing of shot peening machine in the aviation field, and has the ability to independently develop and manufacture core technologies such as automation and intelligence, which can adapt to various changes to support its partners.

For Information:

Shanghai Peetech Equipment Tech Co.,Ltd.

No.1980-1,Waiqian Rd.,201806, Waigang Town, Jiading District, Shanghai City

P.R. China

Tel. +86.021.59529798

Fax +86.021.59570955

E-mail: cindy.zhou@peentech.cn