E-Archive

Articles

in Vol. 2 - March Issue - Year 2001

ZERO A200 Automation Application

indexing turn table

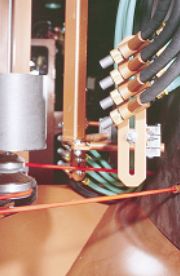

satellites and suction gun

Clemco Industries Corp., based in Washington, Missouri, USA, manufactures manual and automated blast systems under the ZERO brand name. The company offers sample processing service, wherein their technicians test different blast techniques on representative parts supplied by potential customers. Primarily used to determine if automated blasting is feasible, this free service results in a price quotation backed by physical proof of the efficacy of the blast process. For example, an automotive machine shop with a contract to produce parts for a heavy equipment manufacturer needed to deburr fuel injector cases after machining. After extensive experiments in their sample processing lab, Clemco recommended a modified ZERO BNP A200 automatic blast cabinet with precision servo indexer, and a nine-station turntable - three stations for blast, three for blow-off, and three for loading and unloading. At each blast station, three automatic blast guns clean and deburr the parts using #8 glass bead. Two guns have 5/16-inch orifice nozzles, and one has a 3/8-inch orifice. The precision indexing turntable delivers parts to proper position to within + or - .005 inch at 13.5-inch radius. Specially designed urethane fixtures hold and mask the parts during blasting. A 1,200 cfm cyclonic separator reclaims the glass beads. And a three-cartridge, 1,200-cfm reverse pulse dust collector traps the dust and fines removed from the cabinet and from the reclaimer. This automated system replaced the company's hand deburring operation. It produces thousands of perfectly deburred parts much faster than hand finishing or manual blasting.

For information:

Clemco Industries Corp.

Washington, MO 63090, USA

Tel.: +1.636 239 0030

Fax: +1.636 239 0788

www.clemcoindustries.com